mass flow controller working principle

Only Bronkhorst offers so many different models of control valves not just. A volumetric flow measurement is affected by ambient temperature.

Thermal Mass Flow Measurement Principle For Gases Bronkhorst

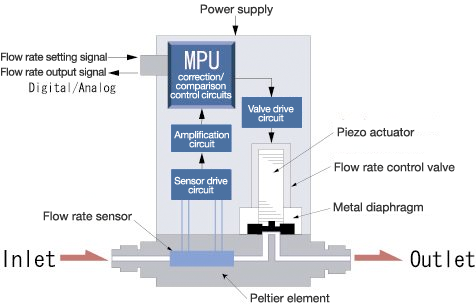

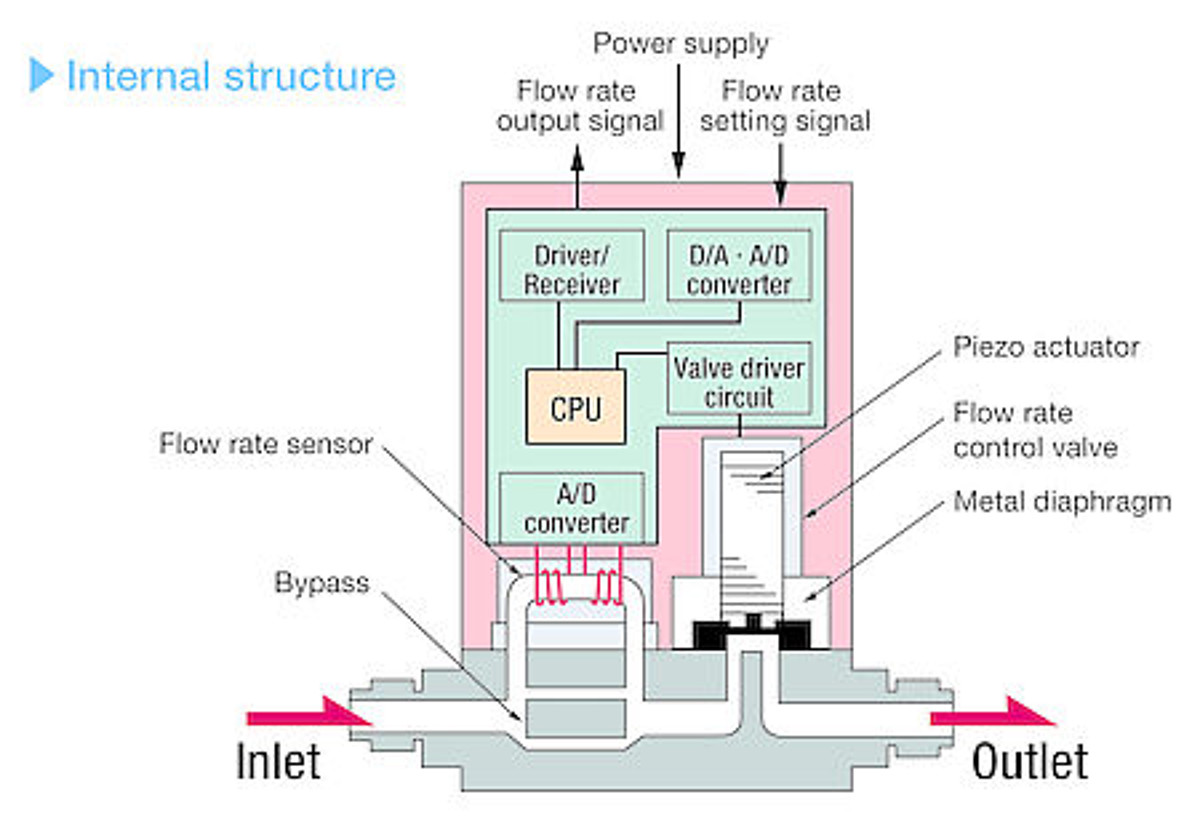

Though they have a piezo actuator valve and an inner contrast control circuit.

. These MFCs are much better suited than a needle v. This is the preferred approach for many of our customers because it is a single instrument to install it is. For setpoints between 2 and 20 MFC Mass Flow Devices have an accuracy of 02 FS.

As the gas flows past the heated sensor its molecules steal. Volumetric flow and mass flow. A mass flow controller is designed and calibrated to control a specific type of liquid or gas at a particular range of flow rates.

The outcome is repeatable results with documented process information. Two physical components make up the sensing element of a flow controller 1 a primary flow channel through which the bulk of the gas flows 2 a secondary flow channel sensor tube through a thin-walled small diameter metal tube with multiple high temperature coefficient windings applied to the external diameter. Thermal mass flow sensors theory of operation design.

211 illustrates the working principle. The relationship between mass flow and volumetric flow is as follows. The flow rate is directly fixed which assures constant flow rate control.

The MFC can be given a setpoint from 0 to 100 of its full scale range but is typically operated in the 10 to 90 of full scale where the best accuracy is. The LV-F series of flow controllers are related to the LF-F series of mass flow meters. In this video from Sierra youll learn the theory and working principles of thermal dispersion mass flow technology that is used in our gas flow meters.

Working principle of thermal Mass Flow Meters Controllers. To truly control any process you must precisely measure what is happening in the feedline in the chamber at every point then use that information in real time to keep the process precisely on-target and productive. Both methods are based on the principle that higher velocity flows result in a more significant cooling effect as.

A thermal mass flow meter measures the movement of a fluid in a pipe or duct. Flow rates can be roughly classified into two types. A mass flow controllers produces repeatable results by automatically adjusting demand when line pressure changes due to other processes happening upstream from your device.

Gas mass flow controller working principle. COVID-19 Coronavirus Information Travel health safety precautions for MKS employees partners. Industrial thermal mass flow meters also known as thermal dispersion or immersible thermal mass flowmeters comprise a family of instruments for precision measurement of total mass flow rate equation of a fluid primarily.

In the case of mass flow control the output signal is continuously compared with a setpoint signal from a voltage source. The mass flow is measured as a function of the difference between the temperature of the heated sensor and the flow stream. The viewpoint change function of the display unit and the pattern setting function are unique to this model and noise resistance has been.

Mass flow controller working principle Thermal mass flow meters employ the thermal dispersion principle whereby the rate of heat absorbed by a fluid flowing in a pipe or duct is directly proportional to its mass flow. The MFC measures the mass flow rate of a gas and controls the flow rate according to a given setpoint. Any deviations between setpoint signal and measured signal are translated into a solenoid control valve adjustment until the two signals are identical.

Mass flow measurement relates to the amount of heat absorbed by the process gas. And converts the mechanical variable mass flow via a thermal variable heat transfer into an electrical signal current or voltage that can be processed by for example a microcontroller. All Mass Flow Controller MFCMeter MFM work at a nominal voltage of 24V DC have a low pressure drop and do not require flow conditioning at the inlet or outlet.

A mass flow controller MFC is a device used to measure and control the flow of liquids and gases. The working range for any mass flux sensor is dependent on the fluid properties such as. Thermal mass flow sensors measure the mass flowrate of gases and liquids directly.

The thermal Mass Flow Meter or Controller is capable of providing direct measurement of mass flow as opposed to most other methods that measure volumetric flow and require separate measurements for temperature and pressure in order to calculate density and ultimately the mass flow. A mass flow controller automatically controls the flow rate of a gas according to a set flow rate sent as an electric signal without being affected by use conditions or changes in gas pressure. Mass flow control technology.

So in this meters simplest configuration gas flows past a heated velocity sensor and a temperature sensor. Principle of operation series 100 thermal mass flow meters parker series 100 mass flow meters mfm incorporate an operating principle based on the thermodynamic properties of the process gas being measured. Mass Flow Controller theory.

Mass Flow ControllerMass Flow Meter With Indicator Kofloc MODEL D8500 SERIES Kofloc mass flow controllermeter driven by a 24 VDC power supply has been developed as a successor to the MODEL 8300. The accuracy from 20 to 100 of Full Scale FS is 1 of Setpoint relative to the calibration gas. Video animation explaining the functions and features of Bronkhorsts MASS-STREAM Mass Flow Meters and Controllers for gases following the direct through fl.

Coriolis Mass Flow Meter Working Principle Coriolis. Mass Flow Rate Density x Volumetric Flow Rate Although volumetric flow under nominal conditions may be accurately calculated the process conditions and fluid properties can vary sufficiently such that it is questionable if the measured volumetric flow rate or derived using velocity represents the. I bought a couple mass flow controllers from eBay to improve the process control of my sputtering chamber.

Volumetric measurements are affected by all ambient and process conditions that influence unit volume or indirectly affect pressure drop while mass flow measurement is unaffected by changes in viscosity density. The mass flow meter uses the principle of capillary heat transfer thermometry to measure the mass flow of gas without temperature and pressure compensation. Structure or Operating principle.

MKS mass flow controllers have thermal and pressure based sensor technologies analog and digital communication and metal or elastomer seals. Then the device works to maintain a constant difference of 50 degrees Celsius between the gas and the heated sensor. As the global leader in precision fluid measurement and control mass flow meter manufacturer.

The flow signal measured by the sensor heating bridge is sent to the amplifier for amplification.

Horiba Fluid Measurement Control Mass Flow Controller

Horiba Fluid Measurement Control Mass Flow Controller

Mass Flow Controller C F Fcon Co Ltd

Mass Flow Controller Mfc Working Principle Bronkhorst

Mass Flow Controllers In Bioprocessing Here Are The Basics Pharmaceutical Processing World

Mass Flow Controller Mfc Working Principle Bronkhorst

![]()

Schematic Of Flow Control Schemes For Mass Flow Controllers Used In The Download Scientific Diagram

Mass Flow Controller C F Fcon Co Ltd

Product Characteristic Of Digital Mass Flow Controller Horiba